9 Simple Techniques For Choosing A Welding Service

Table of ContentsThe Single Strategy To Use For Choosing A Welding ServiceRight Welding Company for BeginnersWelding Companies In New Orleans Fundamentals ExplainedThe Ultimate Guide To Aluminum Welding In New OrleansThe Of Welder Near Me

Pressure vessels are critical parts used in various sectors such as power plants and also manufacturing facilities. As a result of the high-pressure problems under which they operate, appropriate repair and maintenance are essential to guarantee their safety and also performance. Selecting the right for stress vessel repair service as well as maintenance is vital to maintain their durability.The relevance of a Licensed Welding Inspector (CWI) for pressure vessel repairs can not be emphasized enough. While some might argue that the price of hiring a CWI or looking for legitimate R stamp welding solutions is not worth it, it is vital to consider the lasting worth. Although cutting edges might save money and time, it could lead to severe safety and security problems as well as lawful consequences.

Proper close-out documentation is likewise important to guarantee responsibility and traceability for any type of future fixings or modifications. When it involves ASME stress vessel welding, picking the ideal copyright is important. To ensure the safety and security and also efficiency of your stress vessel, you have to consider a number of factors. At Moore's, we understand the significance of safety and high quality in pressure vessel fixings.

What should you think about when selecting a welding service for your stress vessel repairs? Your welder ought to be accredited by ASME's Boiler and also Pressure Vessel Code (BPVC), which controls the qualification of welding, brazing, and also integrating treatments.

The Ultimate Guide To Welding Near Me

But what differentiates a qualified welder from a qualified welder? While a certified welder possesses the needed abilities to generate sound welds, a certified welder has documented and signed qualifications from the business where they function. When it comes to push vessel fixing or changes, making use of a qualified welder is required by law.

To ensure an effective fixing, it's essential to discover a provider with a Qualified Welding Examiner (CWI) that can create a comprehensive repair work procedure customized to your needs. A CWI reviews files such as Welding Treatment Specs (WPS), welder certifications, examination records, task requirements, as well as welding codes to develop the proper repair treatment for the qualified welder to follow.

Pressure vessels under the ASME call for a "tag" also understood as a nameplate (mobile welding near me). When a stress vessel is constructed and also passes its final inspection, the ASME Code mark is stamped onto the nameplate, showing the vessel was developed in accordance with the ASME code standard. When a pressure vessel needs repair, a new stamp will be welded to the shell of the vessel verifying the repair service was done correctly and the pressure vessel has passed assessment

Only R Stamp accredited business are accredited to do this kind of fixing. Ensuring you have a qualified supplier for changing or fixing your pressure vessel means your devices is executing safely as meant.

Welding Near Me - An Overview

This procedure validates the repair work presents a correct hold. The testing must be seen by an Accredited Assessor from The National Board of Boiler and Pressure Vessel Inspectors (NBBI). Your company needs to have a licensed examiner in-house or one they collaborate with to evaluate the repair service quality - mobile welding near me. At the end of the work, your company must be able and also ready to provide a total document of the job performed, including certified product paperwork, product recognition as well as beginning, in-depth work treatments, test records, and QC documentation.

At Moore's, we comprehend the value of choosing a licensed provider for your stress vessel welding demands. If you remain in a pinch as well as need a repair work done promptly, Moore's R Stamp licensed group as well as on-staff CWI work with each other to create a custom repair work treatment for your center needs in a aluminum welding prompt manner.

At Moore's, we comprehend the value of choosing a licensed provider for your stress vessel welding demands. If you remain in a pinch as well as need a repair work done promptly, Moore's R Stamp licensed group as well as on-staff CWI work with each other to create a custom repair work treatment for your center needs in a aluminum welding prompt manner.Welding in an industrial context is, like other kinds of welding, a basic procedure in principle. It essentially entails the mix of high temperature levels, pressure, and also occasionally filler product to make two different parts constant with one another. This enables professionals to protect piping assemblies, repair work heat exchangers, and also execute several various other setup and also repair tasks.

Choosing A Welding Service Things To Know Before You Get This

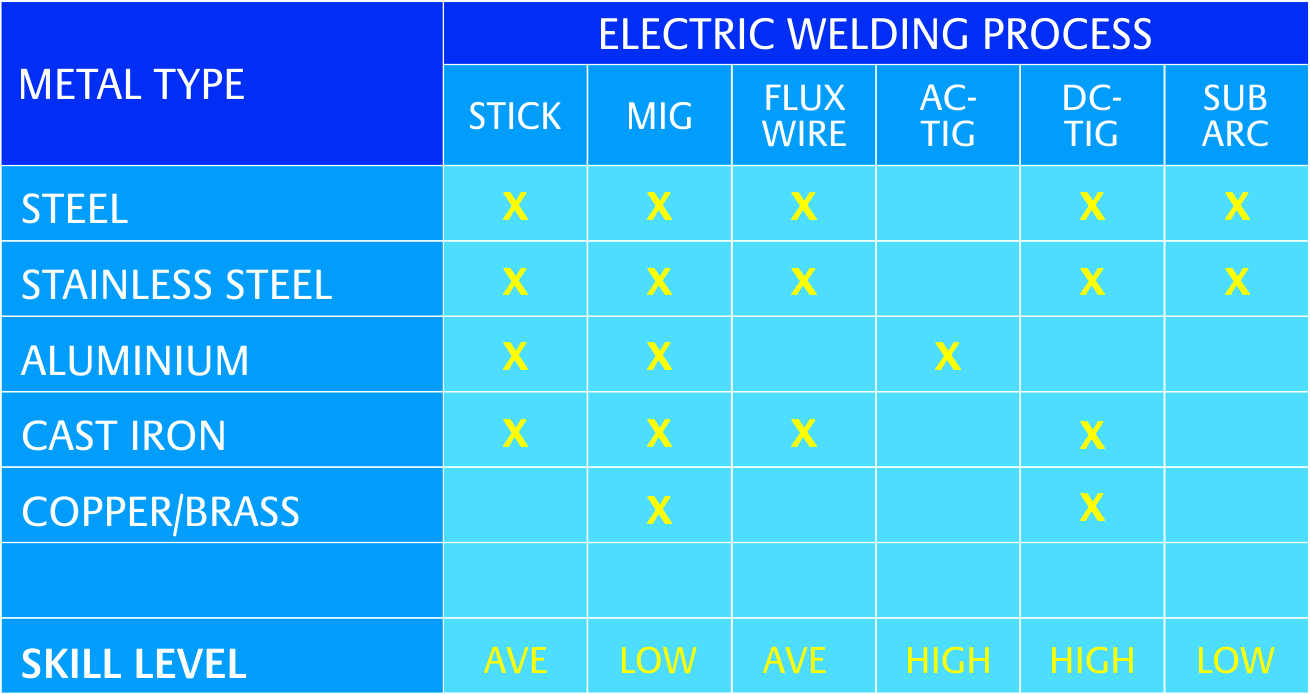

Due to these welding challengescontamination being one significant examplemultiple welding methods have advanced, each with their website link very own purpose, ideal problems, and also optimal welding surface area. To read more regarding these kinds of welding solutions for industrial construction, review our guide to five various kinds of welding services and the welding procedure in its entirety.

The "stick" in this situation is an electrode that conducts electrical power right into the base product, melting the metal to join 2 components together. The electrode has a change coating around it, as well as both the electrode as well as the flux coating progressively thaw as it warms up throughout usage. This flux coating supplies the protecting meant in the nameas it thaws it ends up being a protecting gas that fends off bordering pollutants.

The "stick" in this situation is an electrode that conducts electrical power right into the base product, melting the metal to join 2 components together. The electrode has a change coating around it, as well as both the electrode as well as the flux coating progressively thaw as it warms up throughout usage. This flux coating supplies the protecting meant in the nameas it thaws it ends up being a protecting gas that fends off bordering pollutants.Stick welding is specifically beneficial for rusted metals or areas you have not cleansed beforehand. While this is a versatile strategy helpful for many commercial applications as well as products, it is likewise ideal for thick, significant metals and also it is not tailored to welding thinner steels. Gas Steel Arc Welding (GMAW) is an alternative, one with basic similarities to stick welding with some marked distinctions.

Unlike stick welding, the GMAW electrode does not have a securing change coating. To make up for this absence of protecting, welders pump an exterior securing gas in, frequently inert helium or argon gases. Very comparable to GMAW/MIG welding, Metal Active Gas (MAG) welding pumps in external gases, yet these are a mix of oxygen, carbon dioxide, and argon.

Getting My Aluminum Welding Service To Work

GMAW is best for inside welding and also requires you to clean up the base surface area extensively prior to operating. One more, one that's complicated and also difficult to master, is Gas Tungsten Arc Welding, or TIG which represents tungsten inert gas. Like GMAW, tungsten welding requires an outside protecting gas and a comprehensive preemptive cleansing to prevent contamination.